Key differences between a two-chamber and a three-chamber impact crusher as follows:

Ⅰ.Design and Functionality:

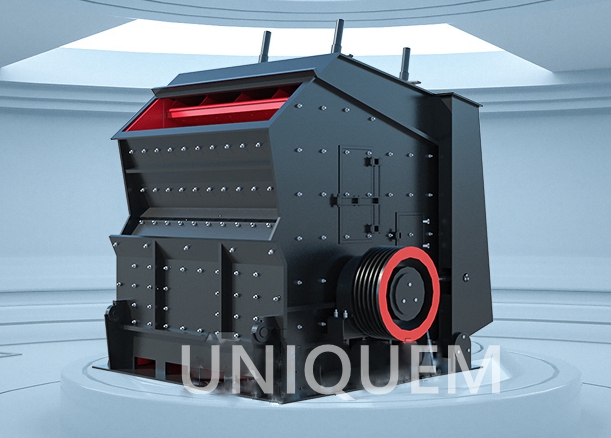

1.Two-Chamber Impact Crusher:

This design typically features two stages of crushing within a single housing.The first chamber (primary) is where the initial reduction of material size occurs.The second chamber (secondary) further refines the material.The material passes through these chambers in a shorter path, leading to a faster throughput.

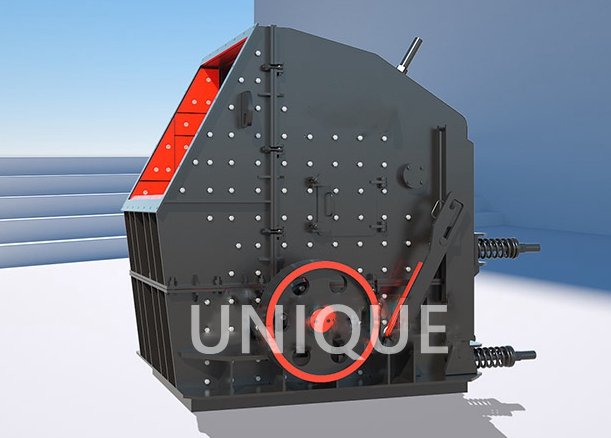

2.Three-Chamber Impact Crusher:

This design incorporates three stages of crushing within the same housing.

The first chamber is for primary crushing, the second for secondary crushing, and the third for tertiary crushing.The additional chamber provides a longer material path and more opportunities for material to be broken down.

Ⅱ.Performance Differences:

1.Throughput and Efficiency:The two-chamber impact crusher often has a higher throughput because the material is crushed more quickly.

The three-chamber impact crusher may have a slightly lower throughput due to the longer residence time and more stages of crushing.

2.Particle Size and Uniformity:The two-chamber design typically results in a coarser end product since it has fewer stages of crushing.

The three-chamber design yields a finer and more uniform end product because the material is exposed to multiple crushing stages, each reducing the particle size further.

Ⅲ.Operational Considerations:

1.Adjustability:The number of chambers can sometimes offer more adjustability in terms of the final product size. In a three-chamber crusher, operators can fine-tune the settings in each chamber to achieve the desired output.

2.Maintenance and Wear:A three-chamber crusher may require more maintenance due to the additional components and impact plates.

Wear parts may need to be replaced more frequently in a three-chamber design because of the increased number of crushing stages.

Ⅳ.Application Suitability:

1.If the primary goal is to maximize production speed and the end product can be larger, a two-chamber impact crusher is often preferred.

2.When the production of a fine, uniform product is the priority, and the operation can accommodate a slightly lower throughput, a three-chamber impact crusher is the better choice.

In conclusion, the choice between a two-chamber and a three-chamber impact crusher depends on the specific needs of the operation, including the desired product specifications, production capacity, and the nature of the material being processed. If you need to know more details ,welcome to contact us to discuss the crusher with UNIQUE engineers.